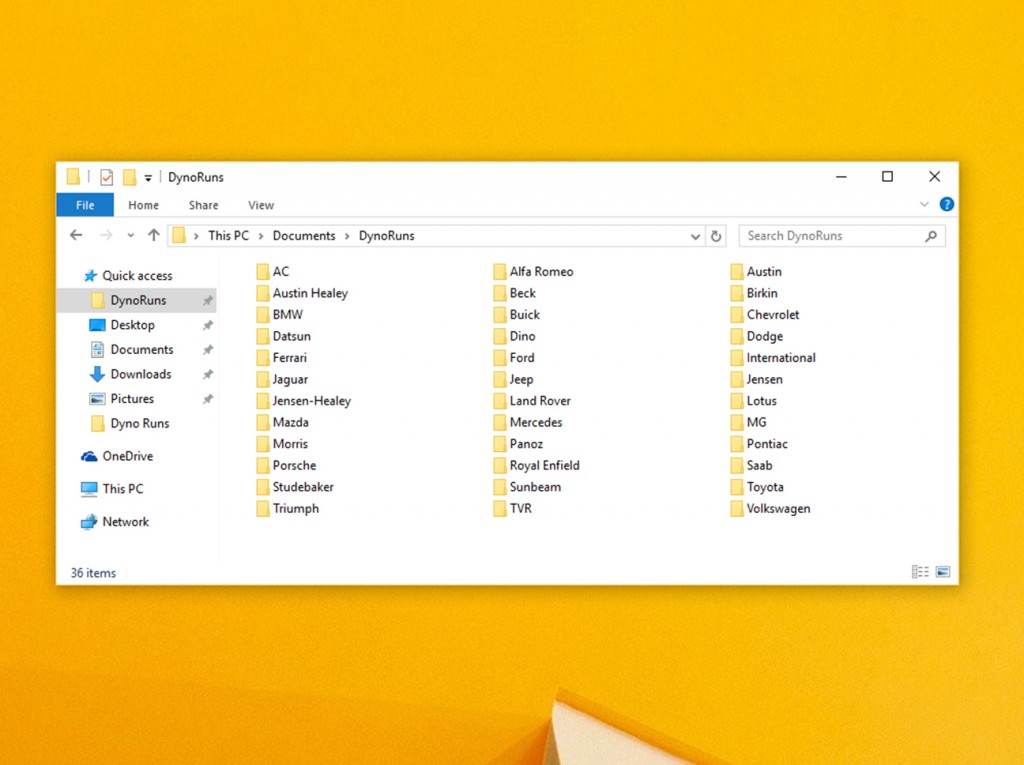

The DynoJet is a great tool for more than just seeing horsepower and torque numbers especially on a car with a small engine. Using the DynoJet on this 1953 Ford Anglia we can scientifically check how the carburetor is functioning, ignition health, top speeds in each gear, and accuracy of the speedometer.

Tag Archives: Skunk River Restorations

1966 Austin-Healey 3000

Progress: 1952 Chevrolet 3100

Tale of Two Octanes

Running this Shelby GT500 Super Snake first on 91 octane pump gas and then on 98 octane Sunoco racing fuel confirmed what we saw two weeks ago with the GT350 that these cars will greatly benefit from higher octane fuels. The Super Snake saw an increase of 46 hp giving it around 740 gross horsepower.

1641cc Crate

50 Years Coming

Fifty years after the original Shelby GT350 a new one is now available in dealerships. Ford rates this 2016 Shelby GT350 at 526 hp but it wasn’t until we drained out the premium pump gas and put 98 octane Sunoco race fuel through it that we were able to see those numbers. To our surprise switching fuels netted a gain of 25.5 horsepower with this car.

Twin Cam Healey

The Lotus engine is rebuilt and sitting again now in the 1973 Jensen-Healey. Without the intake manifold and carburetors mounted the Lotus 907 engine looks tilted 45 degrees. This early Jensen-Healey is only a few hundred before they made the first big revisions to the model. The later Series II and JH-5 models seem more common at shows.

Truck in a Box

Before: 1973 Volkswagen Karmann Ghia

MKUWANA Macubana

Progress: 1973 Triumph Stag

Anglo American Hemi

After: 1955 International Metro

Uncommon Dyno

We have had the DynoJet for just shy of a year now and by the end of the year it will have seen a fair share of interesting makes and models. The DynoJet is great for much more than just finding out how much power or torque a car makes. You can analyze the fuel to air mixture, ignition condition, finding leaks, engine break-in, and even aero dynamic effects on gearing.

Usually too Busy

With the fab shop shut down for the holiday it is a good time to share a glimpse of what we are doing in there. Media blasting, powder coating, metal forming, and welding all happen in this room. We stock around fifty colors of powder and will do from a single part for a walk-in customer to supply production parts for machine shops and manufacturers.